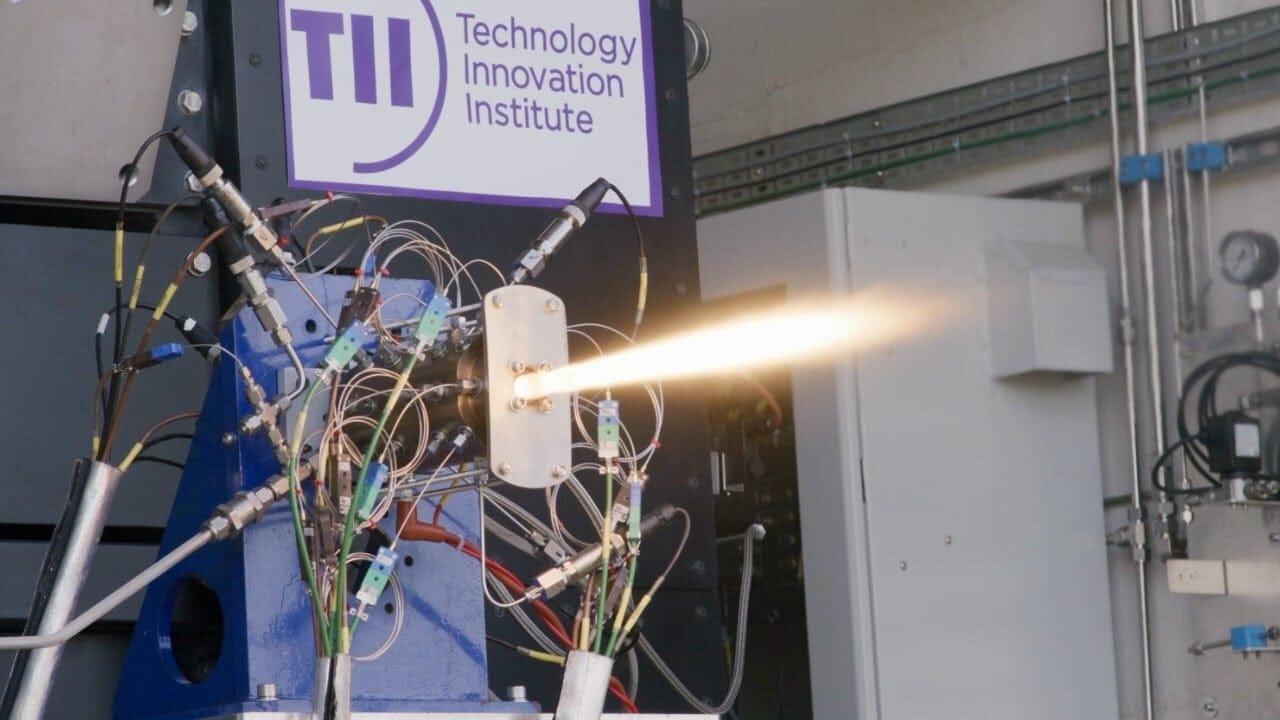

The Technology Innovation Institute (TII) has designed, built, and test‑fired the UAE’s first liquid rocket engine. It is a 250‑newton thruster developed in Abu Dhabi and tested through more than 50 firings. Combustion efficiency reached up to 94%. That puts the UAE on a clearer path to sovereign space technology and local test infrastructure.

- Related reading: UAE now owns almost half of the Middle East space market and TII launches Manarat quantum control platform.

What TII actually built

A compact, liquid‑fuel rocket thruster rated at 250 newtons. This is a class of engine used for small satellite propulsion and orbital adjustments.

- 250 N thrust, equivalent to the force to lift ~25 kg on Earth

- Designed and developed in the UAE

- Built for in‑space tasks like station‑keeping and precision manoeuvres

- Over 50 successful firings during tests

- Combustion efficiency up to 94%

In plain terms, this isn’t a giant launch engine. It’s the kind of hardware that keeps satellites on track, shifts orbits, and points spacecraft where they need to go. Hitting 94% combustion efficiency and surviving dozens of firings shows the design is both mature and repeatable. That reliability is what makes engines useful beyond the lab.

Why a liquid rocket engine matters for the UAE

Liquid engines are the backbone of modern, reusable spaceflight and in‑space propulsion. Building one at home is a capability step, not just a trophy.

- Enables sovereign design and testing of propulsion systems

- Supports orbital manoeuvring and station‑keeping for satellites built in the region

- Lays groundwork for lunar, Martian and deep‑space ambitions

- Keeps talent and IP in the country, not on someone else’s NDA

For the UAE, adding propulsion to its growing space stack closes a critical gap. It means less reliance on overseas suppliers for key spacecraft systems and more control over timelines and upgrades. It also supports the country’s longer‑term ambitions, from science missions to commercial services.

How and where the tests happened

Initial firing campaigns were conducted with Airborne Engineering in the UK as part of an international collaboration. Over 50 firings validated reliability and consistency, which are the metrics that actually matter once you go from a demo to a flight article.

- International test partner: Airborne Engineering (UK)

- Test scope: cold‑flow and hot‑fire sequences

- Outcome: design validated across dozens of firings

- Next: build local test infrastructure in the UAE

The next phase is to bring testing home. Dedicated UAE facilities for cold‑flow and firing will speed iteration, cut logistics overheads, and train local teams on the rigs they’ll use every week. That is how you turn a milestone into a pipeline.

The roadmap from here

TII’s liquid rocket programme is not stopping at one thruster. The plan is to scale propulsion designs and add more advanced cooling and propellant options.

- Scale to larger engines and more thrust classes

- Introduce regenerative cooling for longer burns

- Move towards cryogenic propellants

- Support future deep‑space missions

These steps increase performance and durability. Regenerative cooling, for instance, lets engines run hotter and longer without melting. Cryogenic propellants such as liquid oxygen open better specific impulse, which matters for the delta‑v budgets of serious missions.

Why this fits Abu Dhabi’s wider R&D push

The engine lives inside TII’s Propulsion and Space Research Centre and sits alongside programmes in materials, secure systems and quantum tech. The common thread: build sovereign capability with Emirati engineers working next to international experts in Abu Dhabi.

- Programme centred in Abu Dhabi with a local talent pipeline

- Nine TII research centres across advanced tech fields

- Focus on test infrastructure and repeatable engineering

- Links to national space goals and industry partners

Abu Dhabi wants to own more of the stack, from research to hardware to operations. This thruster project is a textbook example: design at home, test rigorously, then stand up the facilities so the next iteration happens faster. It aligns with the broader trend we’re seeing in the UAE’s space economy too. For context, see our recent piece: UAE now owns almost half of the Middle East space market.

Key specs and milestones at a glance

- Engine type: liquid‑propellant thruster

- Thrust level: 250 newtons

- Efficiency: up to 94% combustion efficiency

- Test count: 50+ firings

- Built: designed and developed in the UAE

- Test sites: Airborne Engineering (UK); UAE facilities planned

- Use cases: station‑keeping, orbital manoeuvres, precision pointing

What this means for satellite makers

If you are building small satellites in the UAE, a domestically developed thruster lowers supply‑chain risk and can simplify licence and export paperwork. Local testing means turnaround is measured in days and weeks, not shipping cycles.

- Shorter lead times and faster iteration

- Easier collaboration on integration and test

- Potential for custom variants tuned for mission needs

Is this a launch engine?No. It is a 250 N in‑space thruster for small satellites and manoeuvring. Launch engines produce hundreds of kilonewtons or more.

Why is 250 newtons useful?It is enough for precise attitude and orbit changes on small spacecraft, without adding big mass or complexity.

Why test in the UK first?Specialist facilities were available there. TII says UAE test infrastructure is underway so future cold‑flow and firing campaigns can happen locally.

What’s next for the programme?Scaling to larger engines, adding regenerative cooling, and moving towards cryogenic propellants, with deep‑space capability in sight.

How does this help the UAE space sector?It builds sovereign propulsion expertise, keeps IP local, and supports both government and commercial missions. For the market context, see our coverage on the UAE’s regional space lead.

Subscribe to our newsletter to get the latest updates and news

Member discussion